Megadumper

The MegaDumper is based on the proven design of the Simpro Dumpmaster and is the safest, most reliable and easy-to-use industrial tipper available. Originally designed for emptying 660L and 1100L MGBs weighing up to 600kg, the MegaDumper can be customised to tip almost any container at heights beyond ten metres.

MEGADUMPER BY ELEPHANTS FOOT

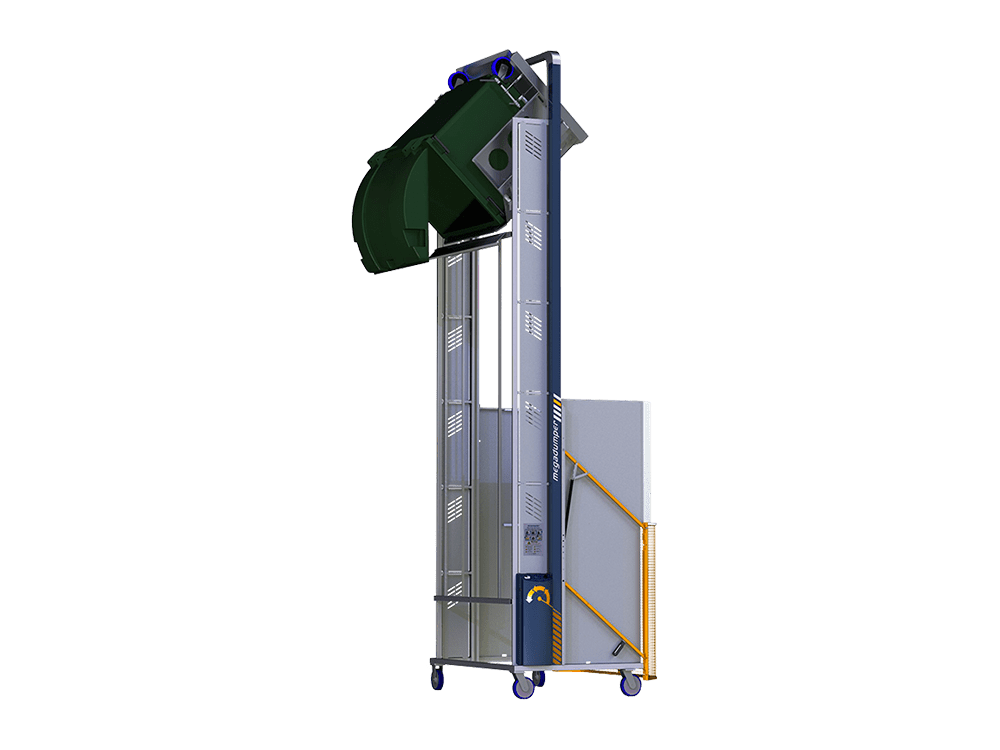

Introducing the Megadumper – an industrial heavy-duty bin lifter that redefines safety, reliability, and ease of use in waste management solutions.

This innovative machine utilises a unique hydraulic action to lift bins vertically, seamlessly and gently invert them over the designated receptacle. The advanced mechanism ensures optimal stability by safely keeping the centre of gravity within the machine’s footprint throughout the entire tipping cycle.

HOW IT WORKS

The Megadumper operates as a heavy-duty industrial bin lifter, with unparalleled efficiency, facilitating a smooth dumping process in less than 30 seconds. This hydraulic system guarantees a secure and controlled tipping motion, maintaining stability while handling loads of up to 600kg.

Originally crafted for emptying 660L and 1100L MGBs, this versatile machine can be customised to tip nearly any container, even at heights surpassing ten metres. Its adaptability makes it an ideal solution for various industrial settings, ensuring optimal waste disposal no matter the container size or weight.

VALUE AND BENEFITS OF THE MEGADUMPER BIN LIFTER

SPACE-EFFICIENT OPERATIONS

Experience efficiency without compromising space. The Megadumper’s innovative design ensures that floor space remains constant, regardless of the tipping height. This means optimal use of space within the waste room while handling substantial loads effortlessly.

UNSURPASSED SAFETY

The Megadumper boasts full-height guarding, a swing-up door with an interlock system, and additional certifications to international standards like ISO 12100, AS/NZS 4024, and CE.

RELIABLE PERFORMANCE

Built to endure the rigours of demanding environments, the Megadumper has proven reliable since its introduction in 1998. Some operators have seamlessly integrated it into their production workflows for over two decades with minimal maintenance requirements.

EASY TO USE

The Megadumper is an incredibly easy-to-use industrial tipper with its user-friendly interface and intuitive operation. Streamlined controls and a straightforward dumping process simplify operation, reducing the need for extensive training and ensuring seamless integration into your workflow.

VERSATILITY

Customisable to accommodate various container sizes and heights beyond ten metres.

MEGADUMPER SUPPORT & CARE

ONBOARDING

Our team always provides you and your team with operational training for waste equipment machinery when we deliver your product and user manual.

The Megadumper is easy to use, with its intuitive interface. However, we’re always here for you on 1300 435 374 if any questions arise.

TEST & TAG

As part of your electrical machinery, our technicians provide test & tag services to ensure that your Megadumper and waste management suite remain compliant.

Learn more about our full range of support and care services for waste management.

TAKE ACTION TODAY!

Revolutionise your waste management process with the Megadumper Industrial bin lifter from Elephants Foot.

Contact us now to explore how the Megadumper can elevate your operations, ensuring safety, reliability, and ease of use. Experience the difference in simplifying your waste disposal needs.

Need something special?

If you have cause for concern about a high volume of specified waste your company produces, please contact us. Our waste management experts can create a specialised order for handling equipment tailored to the special requirements your facilities require.

Contact Us

Leave us a message and a team member will be in touch